- Overview

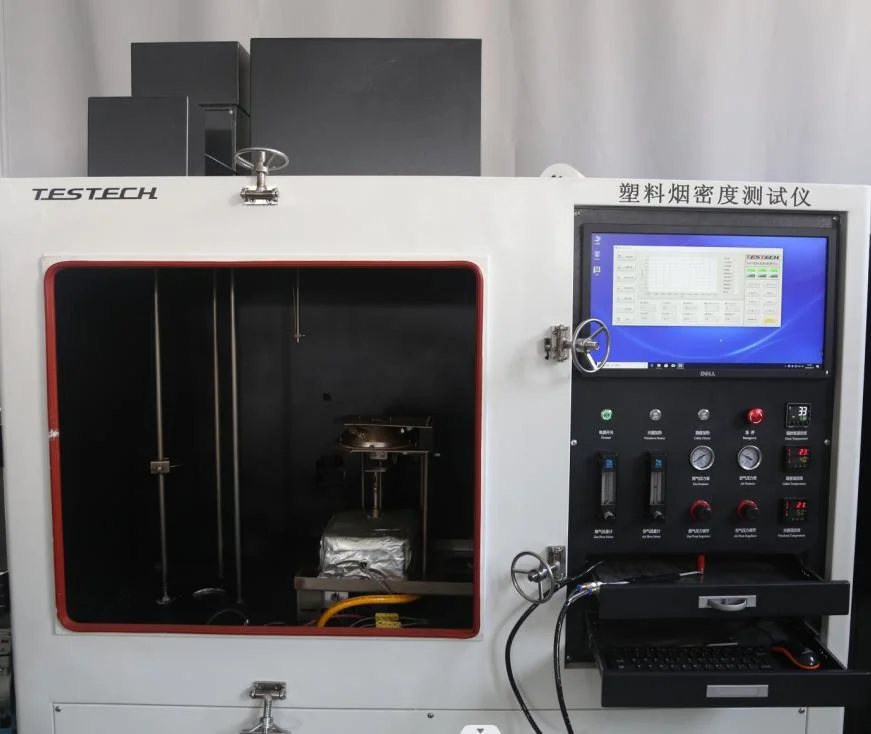

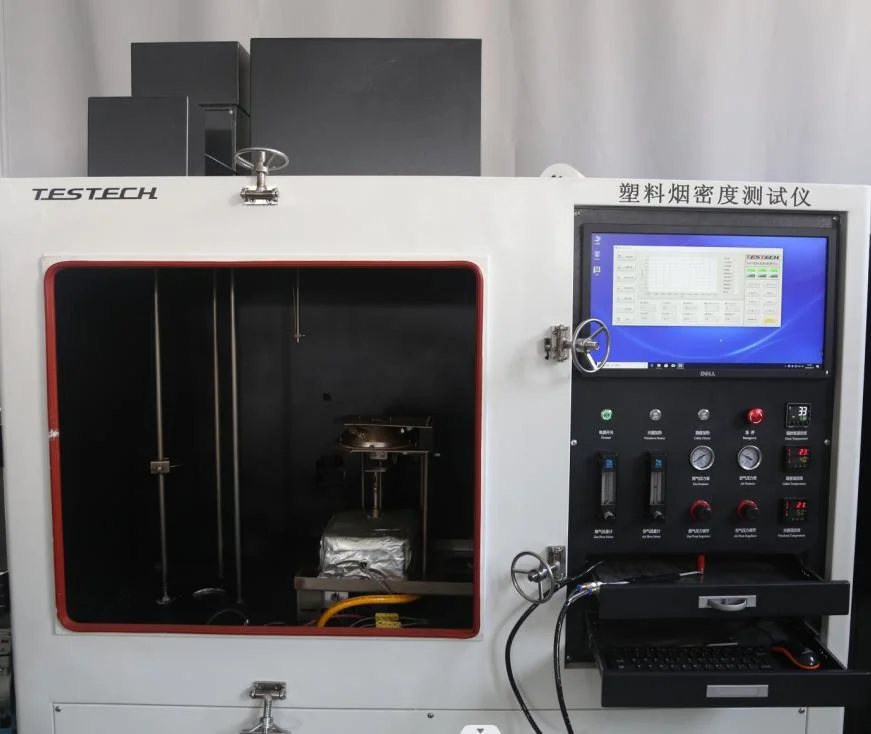

- Detailed Photos

Basic Info.

Model NO.

FTech-ISO5659-2

HS Code

90318090

Production Capacity

100

Product Description

Products

The main principle is to measure smoke density in a particular space, cable or material produced under specific conditions of combustion or radiation. The smoke will couse the beam attenuate when passes through the smoke, the light transmittance be use to calculate ratio of the optical density and smoke density.

This machine is designed according to ISO5659. IT IS with a conical radiant furnace, heat flux can be up 50 kW / m2, and laterally positioned sample, it also can test the sample mass loss rate.

Model:FTech-ISO5659

Standards:

• ISO 5659-1: Plastics - smoke - Part 1: Optical Density Test Principle

• ISO 5659-2: Plastics smoke generated -Part 2: single box test to obtain optical density of the material

Structure:

1, The tester is consist of cabinet, sample case, the radiation cone, ignition, light and measuring devices and other relevant control device component;

2, The structural design and control design considers the ergonomics; The test box is with full door design approach; lock design for easy one-time close the door; optimize operational processes;

3, The test has fully opened door for easy loading and unloading of samples and cleaning the box;

4, The front door hinge installation with Windows and window has block the activity window opaque visor to prevent light from entering the sealed box;

5, The controller is located in the side of the box, easy to operate. When the door is closed does not affect the view controller;

6, Security flameout board, replace the simple, safer operation;

7, Which provides gas measurement port for gas toxicity test;

8, The test box for easy cleaning and coating chemical resistance;

Combustion system:

1, The heating cone: Power 2600W, input temperature range of 0 ~ 1000 ºC, can be stable within ± 2 ºC within 50 minutes, providing irradiance 10KW / m²-50KW / m² of.

2, The use of mass flow controllers and differential pressure sensor can improve the accuracy of piezometers and automatic leak test

3, Ignition with automatic ignition devices; flame length 30mm ± 5mm; in accordance with standards prescribed blue flame with a yellow tip;

Smoke density measuring system:

1, Smoke density and temperature are digital display, viewing more convenient, more accurate values

2, Photodetector assembly includes a photomultiplier, amplified filters, shutters, filters, neutral density filter, a lens, an optical window, and other components;

3, The light source is 6.5V incandescent light sources;

4, The installation of optical cartridge box at the top, light accepted as side-on photomultiplier, light transmission rate of 0.001% accuracy can be achieved

5, Achromatic lens

6, Japan imported Photomultiplier tubes

7, High-gain low-noise amplifier control circuit

Control System

1, Automatic completion of the test; automatic acquisition of various signals; And test report could be print from computer.

2, Brand computers,

3, The printer is optional

4, Voltage: 220V Power 4KW;

5, Customer-owned propane gas;

The main principle is to measure smoke density in a particular space, cable or material produced under specific conditions of combustion or radiation. The smoke will couse the beam attenuate when passes through the smoke, the light transmittance be use to calculate ratio of the optical density and smoke density.

This machine is designed according to ISO5659. IT IS with a conical radiant furnace, heat flux can be up 50 kW / m2, and laterally positioned sample, it also can test the sample mass loss rate.

Model:FTech-ISO5659

Standards:

• ISO 5659-1: Plastics - smoke - Part 1: Optical Density Test Principle

• ISO 5659-2: Plastics smoke generated -Part 2: single box test to obtain optical density of the material

Structure:

1, The tester is consist of cabinet, sample case, the radiation cone, ignition, light and measuring devices and other relevant control device component;

2, The structural design and control design considers the ergonomics; The test box is with full door design approach; lock design for easy one-time close the door; optimize operational processes;

3, The test has fully opened door for easy loading and unloading of samples and cleaning the box;

4, The front door hinge installation with Windows and window has block the activity window opaque visor to prevent light from entering the sealed box;

5, The controller is located in the side of the box, easy to operate. When the door is closed does not affect the view controller;

6, Security flameout board, replace the simple, safer operation;

7, Which provides gas measurement port for gas toxicity test;

8, The test box for easy cleaning and coating chemical resistance;

Combustion system:

1, The heating cone: Power 2600W, input temperature range of 0 ~ 1000 ºC, can be stable within ± 2 ºC within 50 minutes, providing irradiance 10KW / m²-50KW / m² of.

2, The use of mass flow controllers and differential pressure sensor can improve the accuracy of piezometers and automatic leak test

3, Ignition with automatic ignition devices; flame length 30mm ± 5mm; in accordance with standards prescribed blue flame with a yellow tip;

Smoke density measuring system:

1, Smoke density and temperature are digital display, viewing more convenient, more accurate values

2, Photodetector assembly includes a photomultiplier, amplified filters, shutters, filters, neutral density filter, a lens, an optical window, and other components;

3, The light source is 6.5V incandescent light sources;

4, The installation of optical cartridge box at the top, light accepted as side-on photomultiplier, light transmission rate of 0.001% accuracy can be achieved

5, Achromatic lens

6, Japan imported Photomultiplier tubes

7, High-gain low-noise amplifier control circuit

Control System

1, Automatic completion of the test; automatic acquisition of various signals; And test report could be print from computer.

2, Brand computers,

3, The printer is optional

4, Voltage: 220V Power 4KW;

5, Customer-owned propane gas;